English

English

-

Call center (Uzb) :

+998(71) 230 95 94

- OFFICE IN TASHKENT

-

Innovations and technologies

Innovative technologies of Bek Mega Textile

We are implementing advanced automated solutions to improve the efficiency and quality of our textile production.

Modern automation technologies

Bek Mega Textile's production processes utilize a complex of automated systems that help optimize each stage of work:

Modern automation technologies

PROTECHNA - intelligent quality control

- Automatic inspection of 100% of fabric using SMX cameras.

- Real-time data analysis using artificial intelligence algorithms.

- Detection and marking of defects at the production stage.

CRM and ERP systems integration

- Full control over all orders in a single interface.

- Rapid processing of orders and optimization of logistics.

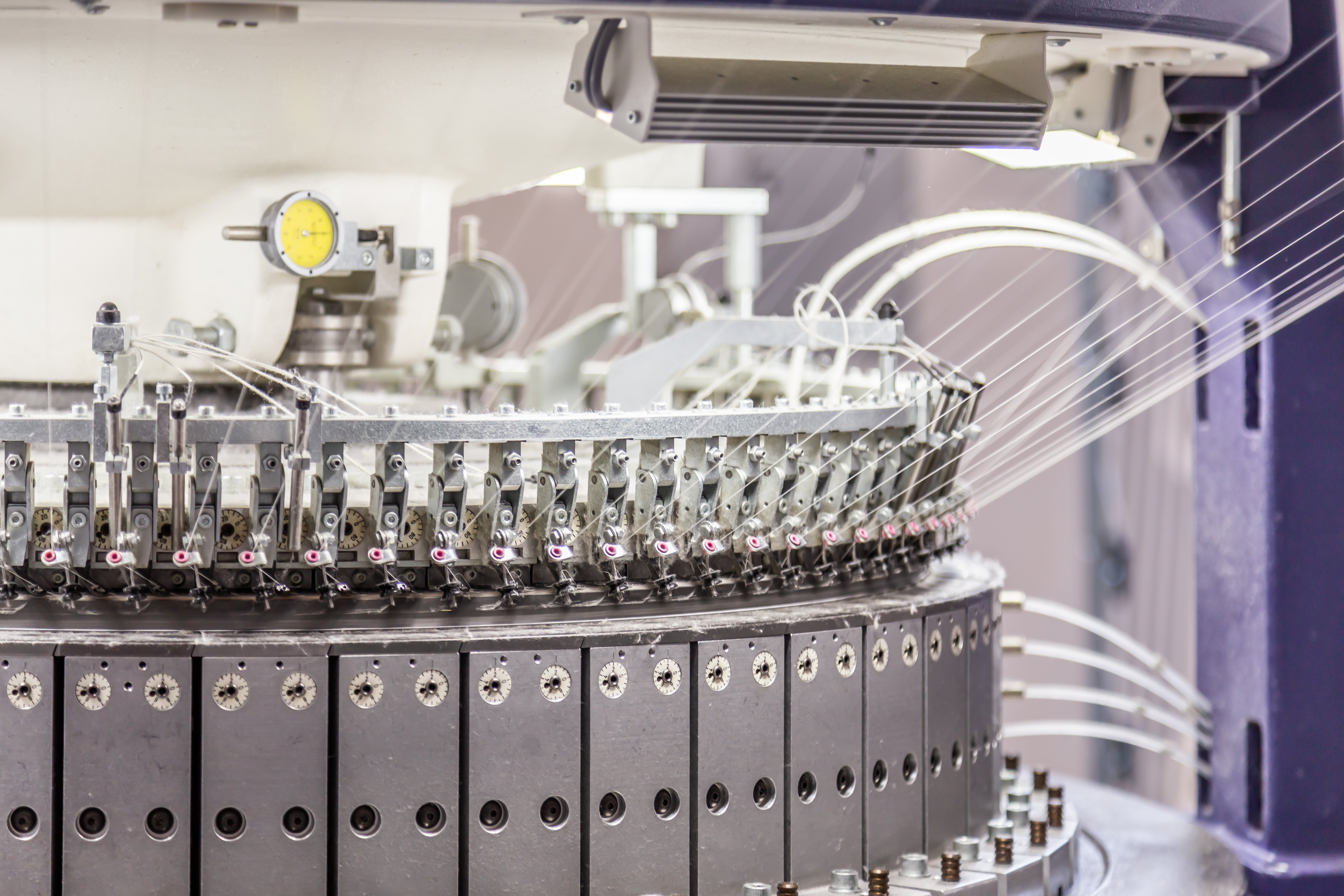

Robotic processes

- Use of automated machines for cutting, knitting, and printing.

- Reduction of human error to minimize mistakes.

Advantages of automationSpeed and accuracy.Reduction of order completion time.Complete precision in dyeing, printing, and quality control processes.Efficiency and waste minimization.Reduction of material and time costs.Optimization of resource and raw material use.КReal-time control.Continuous monitoring of production processes.Sending notifications about possible malfunctions for prompt resolution.Improvement of product quality.Elimination of defects at all stages of production.Compliance with international quality standards.Automated processes at different stages

Advantages of automationSpeed and accuracy.Reduction of order completion time.Complete precision in dyeing, printing, and quality control processes.Efficiency and waste minimization.Reduction of material and time costs.Optimization of resource and raw material use.КReal-time control.Continuous monitoring of production processes.Sending notifications about possible malfunctions for prompt resolution.Improvement of product quality.Elimination of defects at all stages of production.Compliance with international quality standards.Automated processes at different stagesKnitting department

Use of smart cameras to monitor fabric knitting and reduce defects.

Dyeing and finishing

Automation systems regulate the dyeing process to ensure color uniformity and saturation.

Printing department

Robotic machines ensure accuracy in applying complex designs and patterns.

Bek Mega Textile - on the path to innovationOur goal is to create a world-class automated production facility that meets all modern requirements and customer expectations.

Bek Mega Textile - on the path to innovationOur goal is to create a world-class automated production facility that meets all modern requirements and customer expectations.